In the Laboratory of Complex Systems, we probe the transport, rheological, and thermodynamic properties of soft material interfaces in order to understand and predict the system’s flow behavior, stress response, and stability. We are predominantly an experimental group dedicated to the design of custom mechanical devices that can operate on fluid-fluid interfaces, but we also develop our own software and numerical routines for the data collection and analysis. We utilize our experimental and numerical tools to study fundamental problems based on elucidating structure-function-property relationships in 2D fluid interfaces, as well as more applied research on biological soft material interfaces.

Explore our active areas of research:

Interfacial rheometry and design of custom mechanical devices

The complexity of soft material interfaces arises when they are structured due to the presence of species (proteins, particles, polymers) that laterally interact. Aside from thermodynamic (compressibility) effects, the interface can also exhibit its own mechanical properties, which we refer to as interfacial rheology. Having accurate measurements of the interfacial material and mechanical properties is crucial for predicting the evolution, stability, and dynamics of any system where a complex fluid-fluid interface is present. This information is enclosed in the interface’s shear moduli, dilatational moduli, and interfacial tension. One of our lab’s main focuses is the development of a comprehensive repertoire of instruments to accurately measure the mechanical and thermodynamic properties of a variety of fluid-fluid interfaces, under a wide range of flow and deformation conditions.

The UNED LSC group has built and patented the magnetic trap Interfacial Shear Rheometer (ISR), commercialized worldwide under the name of ISR-Flip by the multinational company Biolin Scientific. The magnetic trap ISR utilizes a magnetic needle as a probe that moves along the plane of the interface within a magnetic field created by a pair of permanent magnets to extract the interface’s resistance to shear deformations, and is currently the most versatile and accurate ISR in terms of sensitivity and application range. Additionally, since fluid-fluid interfaces are compressible (unlike 3D liquids and gases at low Mach numbers!), we are developing and expanding our repertoire of Interfacial Dilatational Rheometers (IDRs) that can independently measure an interface’s stress response to compressional and dilatational deformations.

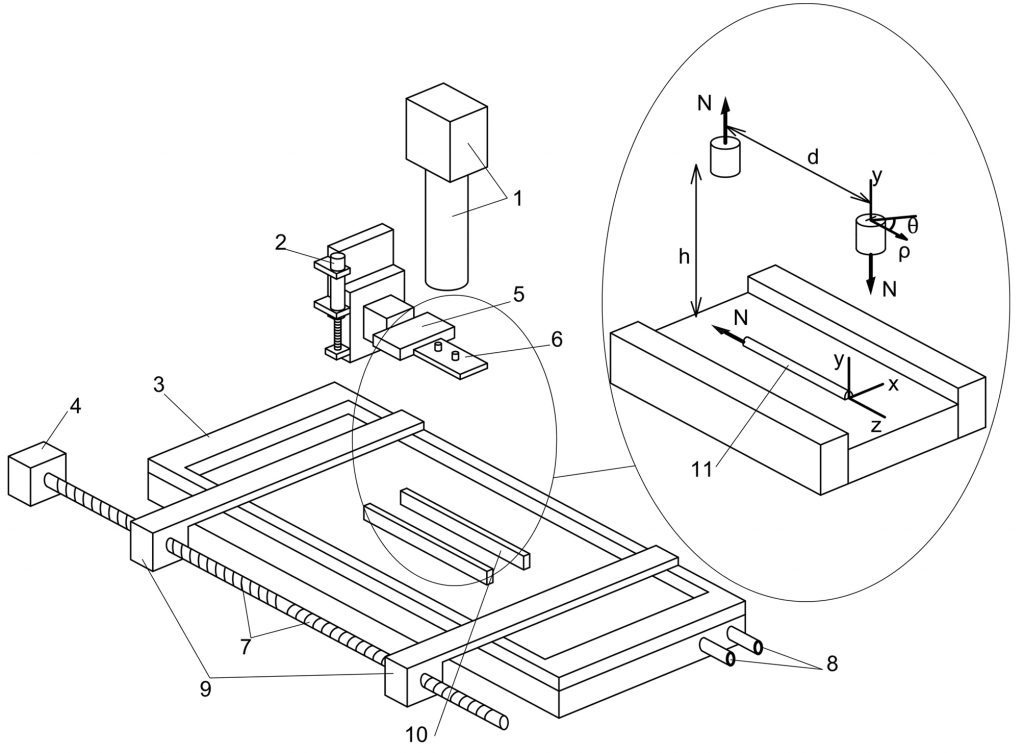

Schematic of the magnetic trap ISR designed by the UNED LSC

Schematic of the rheometer and close-up view of the shear channel + magnetic trap. 1: Microscope and CCD camera. 2: Linear stage to control magnet pair’s vertical position. 3: Teflon Langmuir trough. 4: Stepper motor to control barrier position. 5: Precision linear stage to set z-axis magnet position. 6: Glass window and magnet pair. 7: Lead screw with two counter rotating threads. 8: Circulation bath input and output. 9: Delrin barriers. 10: Delrin channel. 11: Magnetic probe.

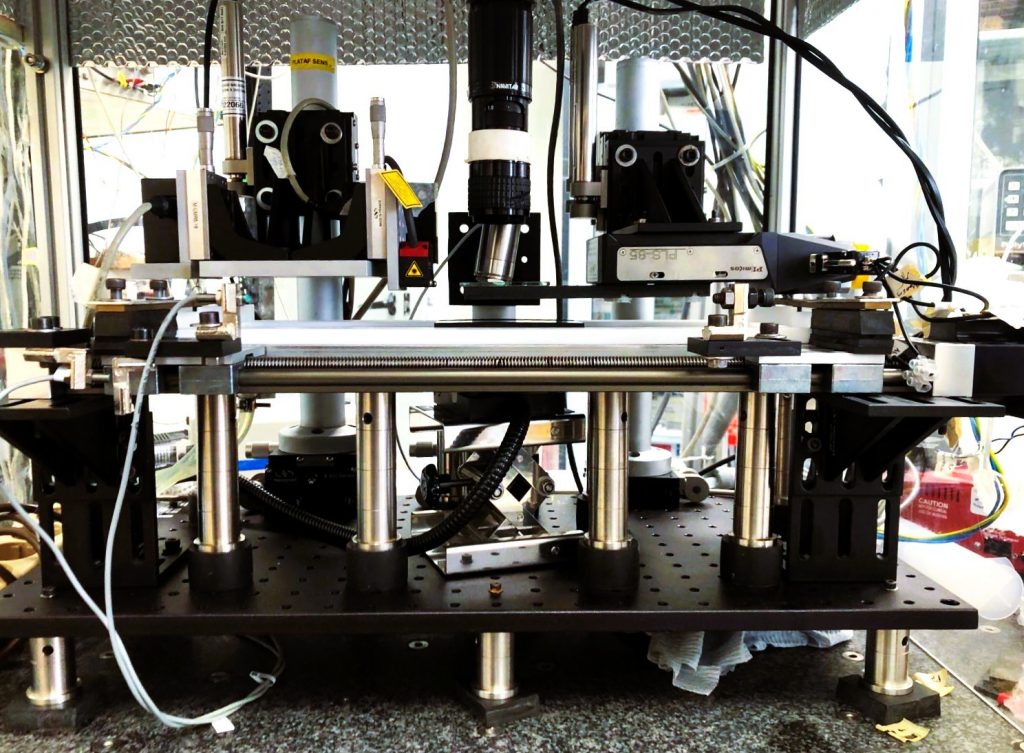

Original magnetic trap ISR device built by the UNED LSC

Original rheometer prototype, fabricated according to the design proposed by the UNED LSC. The controlled motion of the magnets leads to the longitudinal displacement of the needle, which results in a pure shear deformation of the interface. The magnetic trap ISR is the object of several national and European patents (European patent: EP 3330695).

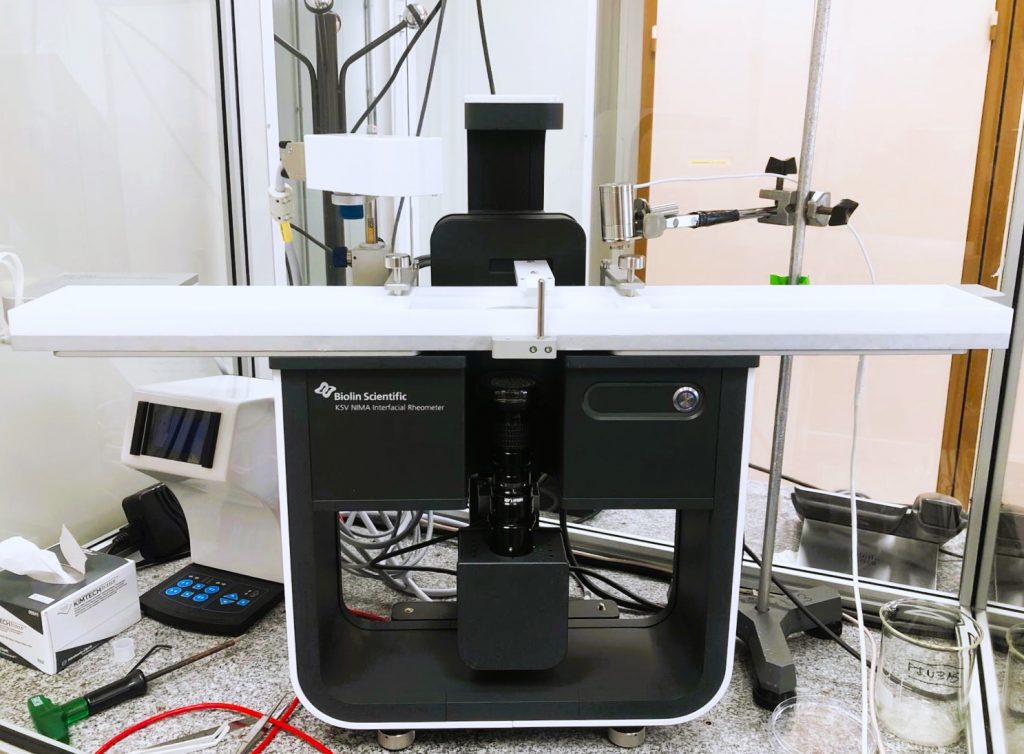

The ISR Flip, commercialized by Biolin Scientific

The UNED LSC group established a formal agreement with the multinational company Biolin Scientific to develop a commercial version of the instrument, known as the ISR Flip. Interested in acquiring this instrument?The ISR Flip can now be purchased directly from Biolin Scientific

Flow-field based data analysis routines

Interfacial shear and dilatational rheometers, such as the ones developed in our lab, are extremely useful tools for understanding how soft material interfaces respond to applied forces and flows since they allow for a rigorous determination of the material functions (or mechanical moduli), which relate the interfacial stress to the interfacial deformation and velocity fields. However, since the interface’s purely mechanical response is coupled with its thermodynamics (interfacial tension), transport at the interface (diffusion, convection, and Marangoni flows), and transport in the bulk (mass and momentum), the raw data obtained from these rheological measurements needs to be properly analyzed and post-processed to extract the true values of the material functions.

The coupling of mass and momentum transport between the interface and the bulk phases requires adequate flow field models to solve for the interfacial and bulk phases components of the total drag exerted on the probe. Such models have allowed us to build a new class of numerical data analysis schemes labelled as flow field-base data analysis (FFBDA). We have developed open-source FFBDA routines for many ISR configurations, including the double wall ring (DWR) ISR, the bicone ISR, and the magnetic trap ISR. Our FFBDA codes take the torque and displacement raw data generated during a measurement, remove the nonlinear contributions to the measured stress arising from the probe’s inertia and bulk flow fields, and return the true values of the interfacial shear moduli. We are currently developing FFBDA schemes for our IDR configurations, which additionally account for dynamic variations in the interfacial concentration arising during area-changing deformations.

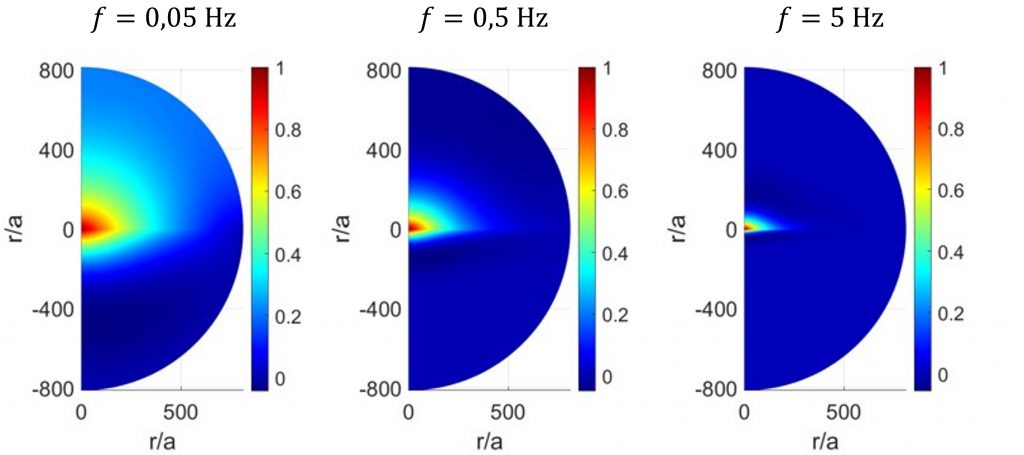

Velocity fields for the magnetic trap ISR geometry

Numerical solutions are obtained for the interfacial and bulk velocity fields generated by the oscillatory movement of a cylindrical probe on the magnetic trap Interfacial Shear Rheometer, for a viscoelastic interface with Boussinesq number Bq = 100. The interface is located on the horizontal plane at r/a = 0 and the top and bottom bulk phases correspond to air and water, respectively. The coupling between the bulk and interfacial momentum fields is apparent, especially at low oscillation frequencies. Notice also how the velocity field changes as the frequency of the probe’s movement is varied; at large frequencies, the interfacial velocity field becomes highly nonlinear, making traditional subphase correction methods (which assume a linear interfacial velocity field) inapplicable.

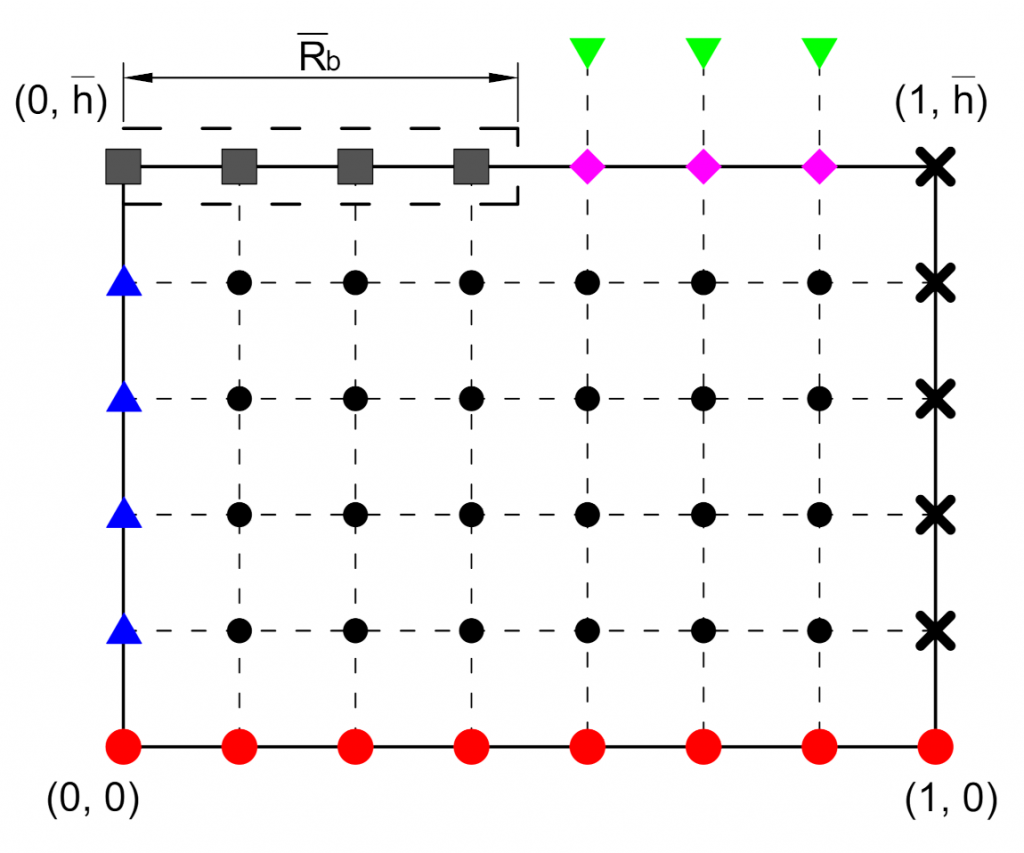

Numerical mesh for FFBDA schemes using the bicone geometry

Mesh used for domain discretization for the bicone interfacial shear rheometer. Blue up triangles: nodes at the cylindrical symmetry axis inside the subphase. Red dots: nodes at the bottom wall of the cup. Grey squares: nodes at the bicone surface. Black dots: nodes inside the fluid subphase. Black crosses: nodes at the outer cup wall. Magenta diamonds: nodes at the interface. Green down triangles: phantom nodes above the interface.

Biologically inspired soft material interfaces

The ubiquity of complex interfaces in natural and artificial processes makes the interfacial rheometers developed in our lab very versatile tools, suitable for interrogating the stress of different complex soft material interfaces, understanding their response to flow and deformation, and obtaining values for their thermodynamic and material properties. Our lab has specifically focused on interrogating different fluid-fluid interfaces relevant to biophysical systems.

Fatty acids play crucial roles in several aspects of human biology, such as fat metabolism or cardiovascular risk, exhibiting a rich range of spatial configurations and phases that yield different orders of magnitude of the interfacial dynamical moduli. Thus, fatty acid Langmuir monolayers (FALMs) are excellent 2D model systems to study the fundamental relationship between the nanoscale morphology and the resulting macroscopic stress response. We have systematically characterized the rheology of several FALMs, showing that, despite the simplicity of fatty acid molecules, a very rich behavior arises as the monolayer’s lateral structure evolves in response to changes in surface pressure and temperature.

Pulmonary surfactants are a are a mixture of lipids and proteins that coat the inner surface of the lung, reducing the energy for breathing and preventing pulmonary collapse. Although the role of interfacial rheology in lung function is recognized, the mechanism by which lung surfactants prevent lung collapse is still unknown. We use the ISRs and IDRs in our lab, along with complimentary imaging techniques, to establish the link between the lung surfactant interfacial architecture and its resulting dynamical properties, particularly focusing on distinguishing between thermodynamic and mechanical effects, elucidating the lateral and longitudinal morphology during inhalation and exhalation, and probing relevant transport and relaxation timescales.

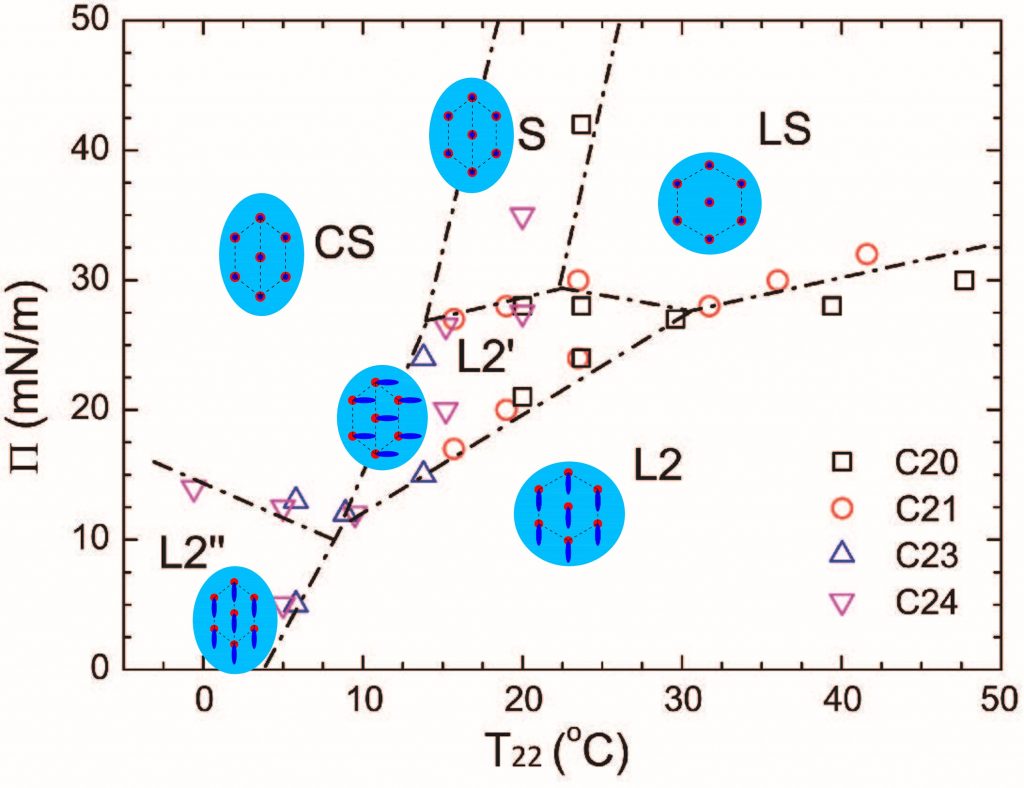

Fatty acid phase diagram

Fatty acids’ phase diagram, obtained from rheological measurements on different fatty acid Langmuir monolayers (FALMs), with varying chain lengths. The temperature scale corresponds to the C22 monolayer, such that the temperatures for the C20, C21, C23, and C24 monolayers have been shifted by their corresponding multiple of (n-22)*5 oC.

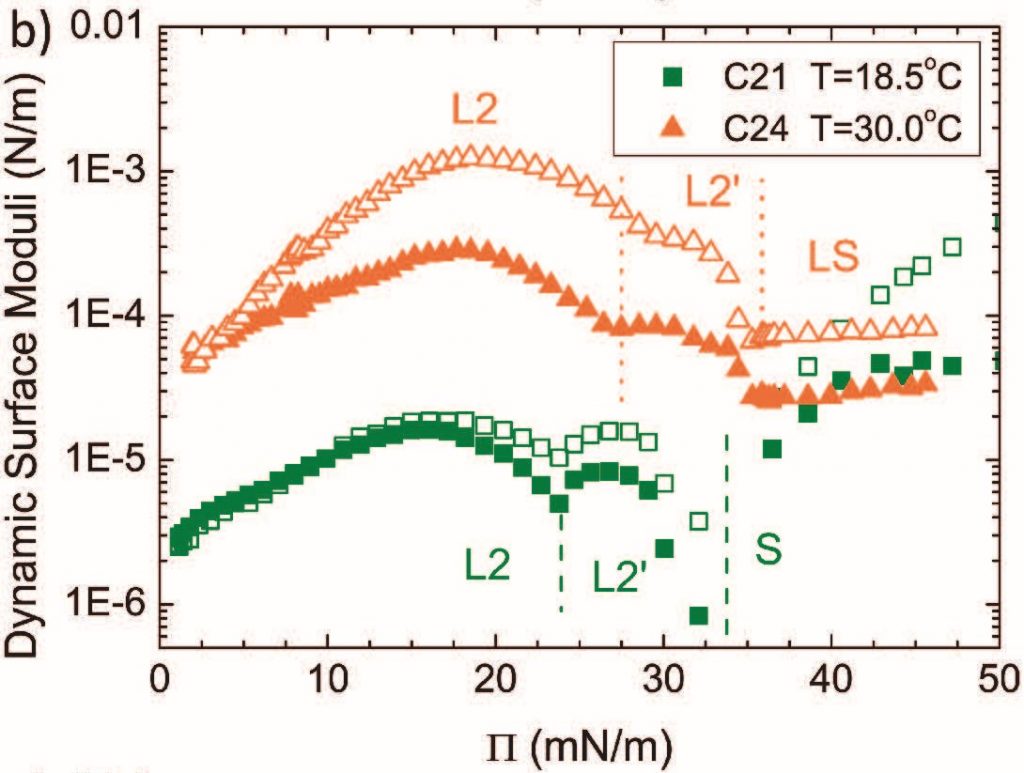

Interfacial rheology of fatty acids

Dynamic surface moduli (storage modulus: solid symbols; loss modulus: open symbols) versus surface pressure for different fatty acids (C21 and C24) and temperatures. Phase changes are depicted by the vertical lines. As the surface pressure increases and the monolayer becomes more tightly packed, the structure changes from a liquid-like to a solid-like configuration.

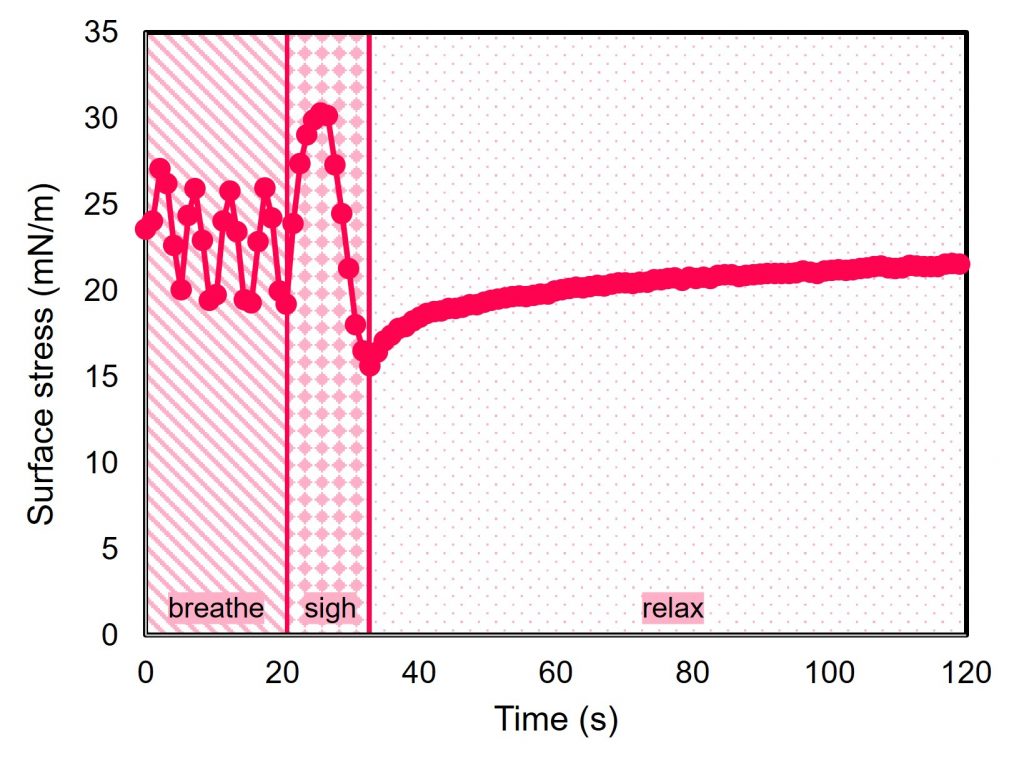

The surface stress in a lung surfactant layer

Interfacial stress of a model lung surfactant interface, subjected to repeated cycles of isotropic compressional and dilatational deformations with amplitudes and frequencies corresponding to ranges of human breathing and sighing maneuvers. Following four breathing cycles and one sigh cycle, the interface is allowed to relax and the temporal evolution of the viscoelastic stress relaxation is measured.